Fixed Dome Type Biogas Plant

- Vivek Kumar

- April 28, 2025

Fixed Dome Type Biogas Plant

Table Of Contents

Fixed Dome Biogas Plants: Powering Life Sustainably

Among various biogas plant designs, the fixed dome biogas plant is notable for its simplicity and effectiveness. It has proven to be a particularly suitable solution for villages and smaller communities aiming for decentralized energy production.

As individuals and communities seek to lessen their reliance on traditional fossil fuels, biogas emerges as a locally sourced alternative with the potential to contribute significantly to a more sustainable energy landscape.

Sustainable energy solutions are vital in today's environmentally conscious world. Biogas, mainly methane, is a versatile and eco-friendly energy source produced through anaerobic digestion of organic materials. This process converts organic waste like agricultural residues, animal manure, food scraps, and plant debris into a valuable energy resource, transforming potential pollutants.

The increasing global emphasis on climate change mitigation and cleaner energy supplies has heightened the appeal of renewable sources like biogas. It offers a locally sourced alternative to fossil fuels, contributing to a more sustainable energy future.

What Exactly is a Fixed Dome Type Biogas Plant?

At its core, a fixed dome type biogas plant features an underground tank, typically constructed from durable materials like bricks and cement, topped with a dome-shaped roof also made of brick or concrete. This dome serves a dual purpose, acting not only as the roof of the structure but also as the storage unit for the biogas produced.

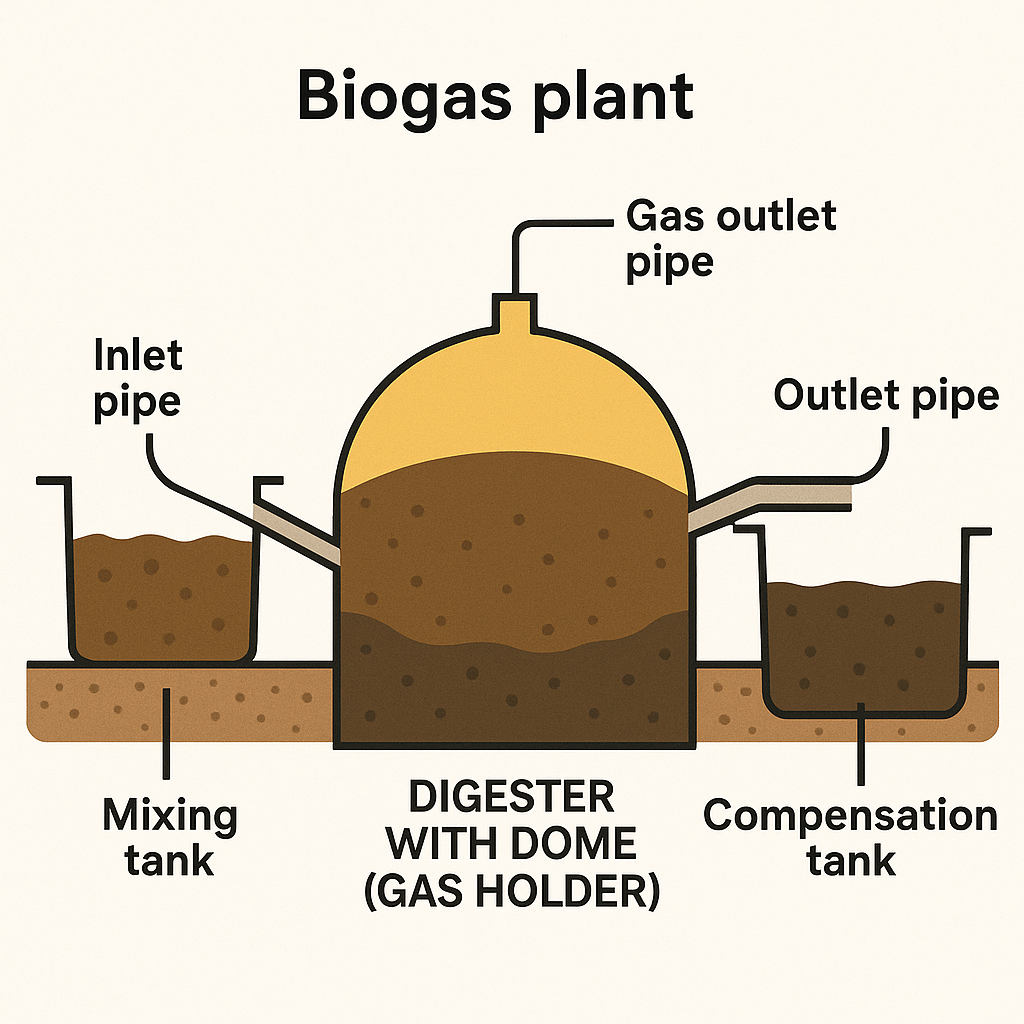

Basic diagram for a fixed dome type biogas plant

The underground placement of the tank provides natural insulation, helping to stabilize the temperature inside. Several key components work together in a fixed dome type biogas plant to facilitate the conversion of organic waste into biogas. These include a mixing tank, where organic waste is combined with water to create a slurry, which then flows into the main digester through an inlet pipe.

The main digester is the sealed underground chamber where the anaerobic digestion process takes place. The dome-shaped roof of the digester is where the biogas accumulates , and an outlet pipe located at the top of the dome allows for the collection and use of this gas. An essential component is the outlet tank or compensation chamber, connected to the digester, which accommodates the slurry displaced as biogas is generated and stored in the dome. This compensation tank plays a crucial role in managing the internal pressure of the digester.

The rigid, immovable dome at the top of the digester in a fixed dome type biogas plant is specifically designed to act as the gas holder. This integrated design, where the dome serves both as the structural top and the gas storage, simplifies the plant's construction and contributes to its overall stability. Unlike other biogas plant types, the gas holder in a fixed dome type biogas plant does not move; it remains a permanent part of the structure.

How a Fixed Dome Type Biogas Plant Works?

Structure and Main Components

- Mixing Tank: Where animal dung (or other organic waste) and water are mixed to form a slurry.

- Inlet Pipe/Chamber: Transfers the slurry from the mixing tank into the digester.

- Digester Tank: An airtight, dome-shaped chamber where anaerobic digestion occurs.

- Dome (Gas Holder): The upper part of the digester acts as a fixed gas storage space.

- Outlet/Compensation Tank: Collects the spent slurry displaced from the digester.

- Overflow Tank: Receives the excess spent slurry for removal and use as manure.

- Gas Outlet Pipe: Withdraws biogas from the dome for use.

Step by Step Working Process

-

Slurry Preparation and Feeding

- Fresh animal dung and water are mixed in equal proportions in the mixing tank to form a slurry.

- The slurry flows through the inlet pipe into the underground digester tank.

-

Anaerobic Digestion

- Inside the digester, anaerobic bacteria decompose the organic matter in the absence of oxygen.

- This process takes about 30–60 days, depending on temperature and other conditions.

- Biogas (mainly methane and carbon dioxide) is produced and starts collecting in the dome-shaped roof.

-

Gas Collection and Pressure Build-up

- The fixed dome acts as a non-movable gas holder, storing the biogas at the top of the digester.

- As more gas accumulates, pressure increases, forcing the slurry downward and into the outlet/compensation tank.

-

Slurry Displacement and Removal

- Continued gas production pushes the spent slurry out of the digester into the overflow tank.

- The spent slurry is periodically removed and can be dried and used as organic manure.

-

Biogas Utilization

- The collected biogas can then be drawn from the top of the dome through an outlet pipe and utilized as a clean and renewable fuel for various applications, including cooking, heating, lighting, and powering engines.

- Furthermore, the digested slurry, now referred to as bio-slurry, is periodically removed from the overflow tank of the compensation chamber.

- This bio-slurry is rich in nutrients and serves as an excellent natural fertilizer for agricultural purposes.

- A valve regulates the flow of gas for household or agricultural use, such as cooking or heating.

Key Features and Advantages

- No Moving Parts: The fixed dome design has no moving or rust-prone components, ensuring durability (often 20+ years).

- Underground Construction: Protects the digester from temperature extremes and physical damage, and saves space.

- Low Cost and Maintenance: Simple construction and operation, with local materials often used.

- Byproduct Use: The spent slurry is nutrient-rich and serves as an excellent fertilizer.

Also Read: Top 10 Biogas Companies in India

Benefits of Choosing a Fixed Dome Type Biogas Plant

Low Construction and Maintenance Costs

- Fixed dome biogas plants are relatively inexpensive to construct due to their simple design and use of locally available materials like brick masonry, eliminating the need for costly steel components.

- The absence of moving parts minimizes maintenance requirements and reduces the risk of mechanical failure, further lowering operational costs.

Long Lifespan and Durability

- These plants are highly durable, with lifespans typically ranging from 10 years to over 20 years, and in some cases, up to 50 years.

- Underground construction protects the plant from physical damage, rust, and temperature fluctuations, contributing to its longevity.

Efficient Waste Management and Environmental Benefits

- Fixed dome biogas plants convert organic waste (such as animal dung and food scraps) into biogas, effectively managing waste and reducing environmental pollution.

- The process reduces greenhouse gas emissions by capturing methane that would otherwise escape into the atmosphere, aiding climate change mitigation.

Production of Clean, Renewable Energy

- Biogas produced is a clean, renewable energy source that can be used for cooking, heating, lighting, and even electricity generation, reducing dependence on firewood, coal, or other non-renewable fuels.

- This helps reduce indoor air pollution and deforestation, improving community health and environmental sustainability.

Generation of Valuable Byproducts

- The slurry left after biogas production is nutrient-rich and serves as an excellent organic fertilizer, enhancing soil fertility and agricultural productivity.

Energy Security and Rural Empowerment

- Fixed dome plants provide a reliable, on-site energy source for rural households, farms, and small communities, promoting energy independence and supporting rural development.

- The technology is accessible and can be managed by local communities, fostering self-sufficiency and local employment.

Economic Viability

- Besides saving on fuel costs, surplus biogas or fertilizer can provide additional income streams for farmers and small communities.

Fixed dome biogas plants are a practical, sustainable, and cost-effective solution for clean energy production, waste management, and rural development, especially in regions with abundant organic waste resources.

Limitations of the Fixed Dome Type Biogas Plant

Despite the numerous advantages, the fixed dome type biogas plant also has certain limitations that are important to consider.

- Gas Leakage and Gas-Tightness Issues: Fixed dome biogas plants are prone to gas leakage due to the difficulty in achieving a completely gas-tight structure, especially in the brickwork of the gas holder. Even small cracks or porosity in the dome can cause significant biogas losses.

- Fluctuating and High Gas Pressure: The pressure of gas inside the fixed dome is not constant. It fluctuates substantially depending on the amount of gas stored, and can become quite high, making it unsuitable for applications requiring steady gas pressure (e.g., engines) unless additional pressure regulation equipment is installed.

- Construction Requires Skilled Labor: Proper construction of fixed dome biogas plants demands experienced and skilled technicians. Poor construction quality can lead to operational problems, particularly with gas-tightness and structural integrity.

- Potential for Structural Cracks: Over time, structural cracks or holes can develop in the dome, leading to gas leakage and reduced plant efficiency. This risk is heightened if construction materials or workmanship are substandard.

- Temperature Sensitivity: The underground structure can result in low digester temperatures, especially in colder climates, which slows down the digestion process and reduces gas production efficiency.

- Difficult Maintenance and Repairs: Once constructed, repairs to the fixed dome (especially for leaks or cracks) can be difficult and costly, as the gas holder is integrated into the structure and not easily accessible.

- Limited Gas Storage Capacity: The gas storage capacity of fixed dome plants is relatively low. This makes them less suitable where large or highly variable gas demands exist, as the plant cannot buffer large amounts of biogas.

- Initial Construction Cost: Although fixed dome plants have low long-term costs due to their durability and lack of moving parts, the initial construction cost can be relatively high, especially for larger digesters.

- Complex Operation and Maintenance: The digestion process is complex, and the plant can be more difficult to operate and maintain compared to simpler designs. Skilled operation is often required to ensure optimal performance.

- Formation of Scum: The formation of scum within the digester can sometimes occur , and there is a possibility of grit and stones accumulating at the bottom of the digester over time.

- Not Ideal for All Soil Types: Fixed dome plants are best suited to areas where the soil is stable and impermeable. In unsuitable soils, alternative designs may be preferable.

Where Can a Fixed Dome Type Biogas Plant Be Used?

Suitable Locations for Fixed Dome Type Biogas Plants

Fixed dome type biogas plants are versatile and widely used, particularly in rural and semi-urban settings. Here’s where they can be most effectively used:

- Villages and Small Communities: These plants are especially popular in villages or small communities where organic waste such as animal dung, food scraps, and agricultural residues are readily available.

- Farms and Households: They are ideal for individual families, small farms, or groups of households that generate consistent organic waste. In India, many rural families use small fixed dome biogas plants (typically 2–3 cubic meters in size) for daily cooking and lighting needs.

- Dairy and Poultry: Dairy and poultry farmers, as well as cow shelters and small-scale industries, can particularly benefit from this technology.

- Areas with Skilled Supervision: Since construction quality is crucial for gas-tightness and durability, fixed dome biogas plants should be built where experienced biogas technicians can supervise the process.

- Regions with Mild to Warm Climates: Being constructed underground, these plants are protected from low temperatures at night and during cold seasons, making them suitable for regions where the ground does not freeze deeply. However, in very cold climates, the digester may take longer to heat up and may be less efficient.

Alternative: The Floating Gas Holder Type Biogas Plant

An alternative design to the fixed dome type biogas plant is the floating gas holder type biogas plant. This type also features an underground digester, but instead of a fixed dome, it utilizes a movable, dome-shaped gas holder, typically constructed from steel, that floats directly on the surface of the slurry within the digester.

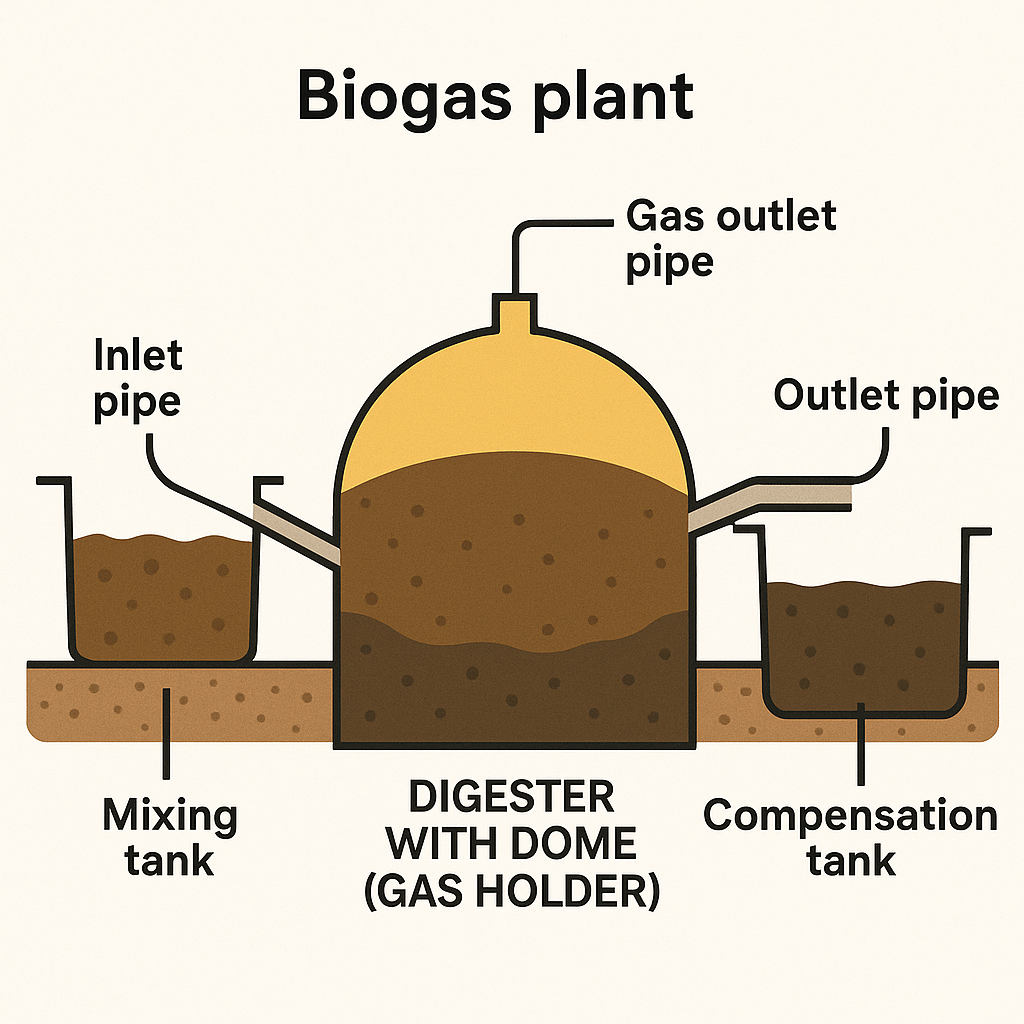

Basic diagram for a floating gas holder type biogas plant

As biogas is produced through anaerobic digestion, it is trapped within this floating gas holder, causing the holder to rise. The extent to which the gas holder has risen provides a visual indication of the volume of biogas currently stored. The biogas is then supplied at a relatively constant pressure, determined by the weight of the floating gas holder.

If a higher gas pressure is required, additional weights can be placed on top of the gas holder. Some floating gas holder type biogas plants incorporate a water jacket around the gas holder to prevent it from becoming stuck if a layer of scum forms on the slurry surface.

Key Differences: Fixed Dome Type Biogas Plant vs. Drum Type Biogas Plant

1. Gas Holder Design

Fixed Dome: Uses a non-movable brick/cement gas holder integrated into the digester structure. Gas pressure fluctuates based on slurry displacement into the compensation tank.

Floating Drum: Features a movable steel/plastic drum that rises/falls with gas accumulation, maintaining constant pressure via buoyancy.

2. Construction & Materials

Fixed Dome:

- Built with brick masonry or ferro-cement, requiring skilled labor for gas-tight construction

- Lower material costs (no steel parts) but prone to cracks/leaks if poorly constructed

Floating Drum:

- Includes a steel drum (or plastic/glass-fibre variants) prone to corrosion (5–15-year lifespan)

- Higher initial costs due to metal components and maintenance (painting, rust prevention)

3. Operational Characteristics

Gas Pressure:

- Fixed Dome: Pressure varies with gas volume, complicating direct use for engines

- Floating Drum: Delivers stable pressure ideal for cooking/appliances

Visibility:

- Floating Drum: Gas volume is directly observable via drum position

- Fixed Dome: Gas storage not visible, requiring gauges for monitoring

4. Durability & Maintenance

Fixed Dome:

- Longer lifespan (20+ years) if properly sealed

- Difficult to repair leaks in underground masonry

Floating Drum:

- Shorter lifespan due to corrosion but easier to repair/replace the drum

- Requires regular maintenance (painting, scum removal)

5. Cost & Suitability

Fixed Dome:

- Cheaper to construct (e.g., Deenbandhu model costs ~45% less than comparable drum plants)

- Best for stable substrates and skilled construction teams

Floating Drum:

- Higher upfront costs but simpler operation

- Ideal for high-solids feedstocks and seismic zones

6. Environmental Impact

Fixed Dome: Risks methane leaks from cracks or the compensation tank

Floating Drum: Steel production and corrosion waste pose environmental concerns

Deenbandhu Model: Fixed Dome Type Biogas Plant

The Deenbandhu model is a widely adopted, cost-effective fixed dome biogas plant design in India, developed in 1984 by Action for Food Production (AFPRO) in New Delhi. Its name, meaning "friend of the poor," reflects its focus on affordability and accessibility for rural households and small-scale agricultural users.

Deenbandhu Fixed Dome Type Biogas Plant Model and Diagram

Key Features

- Design Philosophy

- Prioritizes low construction cost and simplicity.

- Spherical, dome-shaped digester and gas holder minimize surface area, reducing earthwork and material costs without sacrificing efficiency.

- Built primarily with brick masonry and cement mortar for durability and longevity.

- Structural Overview

- The plant consists of a hemispherical dome (gas holder) attached to a concave-bottomed digester.

- Inlet and outlet tanks are connected for feeding slurry and removing digested residue.

- The gas collects under the dome and is piped out for use; digested slurry exits through a side opening.

- The Deenbandhu 2000 is an improved version with a dome-shaped outlet tank, further reducing material use and costs by up to 16% compared to earlier models.

- Construction and Operation

- Does not require steel or moving parts, reducing risk of corrosion and maintenance needs.

- Built underground, which helps maintain temperature and saves space.

- Can be constructed in capacities ranging from 1 to 6 cubic meters per day.

- Designed for ease of repair and maintenance by local users, including farmers.

- Cost and Adoption

- A 2 m³ Deenbandhu plant costs approximately Rs. 7,600–8,000 (excluding gas piping and appliances).

- Over 90% of biogas plants in India are of the Deenbandhu type.

Advantages

- Lower construction cost compared to other models (e.g., floating drum KVIC model).

- Long service life due to robust construction materials.

- No moving parts, minimizing maintenance.

- Underground installation conserves space and maintains warmth for efficient biogas production.

- Supports rural employment through local construction.

Limitations

- Potential for gas leakage if cracks develop in the dome.

- Gas pressure can fluctuate.

- Biogas production efficiency drops in colder climates unless properly insulated.

Technical Specifications (for a 2 m³ plant)

| Component | Dimension/Feature |

|---|---|

| Main tank diameter | 3,100 mm |

| Main tank depth | 2,304 mm |

| Dome radius | 1,400 mm |

| Dome height (center) | 1,400 mm |

| Wall thickness (main tank) | 150 mm |

| Wall thickness (dome) | 75 mm |

| Inlet pipe length | 1,800 mm (150 mm diameter) |

| Outlet chamber | 1,380 mm x 1,845 mm (rectangular) |

| Outlet slurry opening | 600 mm x 565 mm |

Construction Process Highlights

- Site selection and soil preparation.

- Excavation and foundation laying.

- Construction of the dome using radial brickwork and plastering for gas-tightness.

- Installation of inlet/outlet tanks and gas piping.

- Final testing for gas leaks and commissioning.

Summary Table: Deenbandhu vs. Other Fixed Dome Models

| Feature | Deenbandhu Model | Janata Model |

|---|---|---|

| Shape | Spherical dome, concave bottom | Cylindrical, dome top |

| Construction Material | Brick masonry, cement mortar | Brick masonry, cement |

| Cost | Lower | Higher |

| Outlet Tank | Rectangular (Deenbandhu), Dome (Deenbandhu 2000) | Rectangular |

| Maintenance | Simple, user-friendly | Moderate |

| Adoption in India | >90% of fixed dome plants | Less common |

The Deenbandhu model is India’s most popular fixed dome biogas plant, offering an affordable, durable, and efficient solution for converting livestock and organic waste into clean energy. Its design simplicity, low cost, and adaptability make it especially suitable for rural households and small farms.

Conclusion

In conclusion, the fixed dome type biogas plant presents a viable and sustainable pathway to harnessing clean energy from organic waste. While it comes with certain limitations, its advantages, particularly its affordability, durability, and space-saving underground design, make it a compelling option for a wide range of users, especially in rural and developing regions.

By understanding the principles behind its operation and the benefits it offers, individuals and communities can make informed decisions about adopting this technology to meet their energy needs in an environmentally responsible manner.

Ensuring proper construction and consistent maintenance are crucial for maximizing the performance and lifespan of a fixed dome type biogas plant, ultimately contributing to a more sustainable and resilient future.